14HE Optical Comparator

The 14HE bench top comparator is Dorsey Metrology's basic and most economical comparator with the same high quality features as the other comparators in our product line, but in a smaller... Learn More14H Optical Comparator

The Benchmark 14H is an Erect Image benchtop comparator and is another example of our expanding range of products. This new comparator has the same high quality features as the current product line,... Learn More16H Optical Comparator

This extremely versatile measurement instrument features a robust cast granite composite base and our proven cast iron "ultra precision" stage system. This comparator comes standard with... Learn More16VS Optical Comparator

This dynamic vertical optical system is the first of its kind manufactured in the USA. This system allows a much greater stage capacity up to 50 pounds (15 lbs in the center of the glass plate) with... Learn More24P Optical Comparator

The 24P is designed to be an all purpose measurement/inspection instrument capable of performing both light and heavy duty tasks. Choose any lens system to customize this machine to match your... Learn More32P Optical Comparator

The 32P was designed with crisp, clear telecentric optics and a precision solid cast iron stage to be an instrument capable of handling almost any measurement/inspection requirement. This welded... Learn More32SS Optical Comparator

The 32SS offers the same quality features as the 32P Horizontal Beam comparator, however the 32SS offers an offset screen for working with large overlay applications. This machine has an erect... Learn MoreOptical Comparator Charts

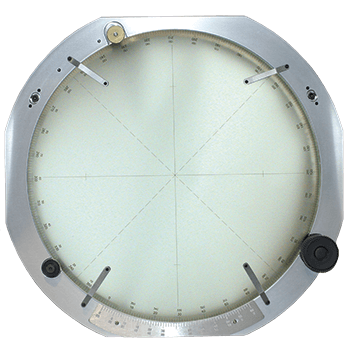

Dorsey Metrology uses satin ground glass of superior quality for all our optical comparator glass charts. The charts are very durable and will last for many years with proper care. Glass charts... Learn More

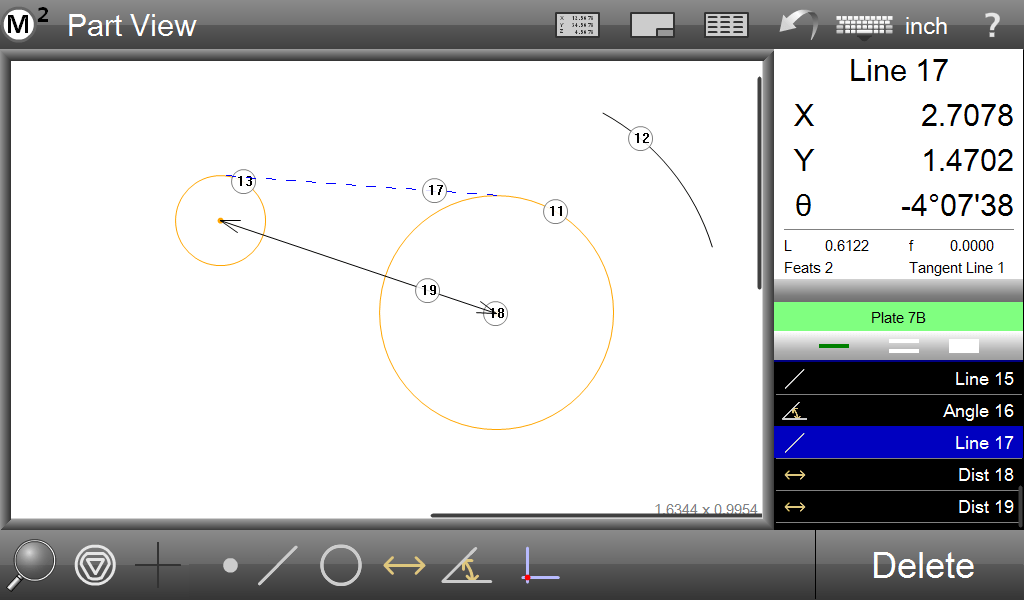

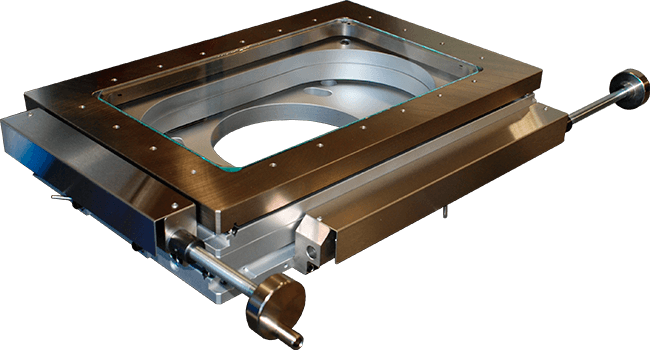

Optical Comparator Stages

These precision coordinate stages can be used for optical comparators, vision systems or microscopes. Each stage features heavy duty crossed roller bearings.